Environments

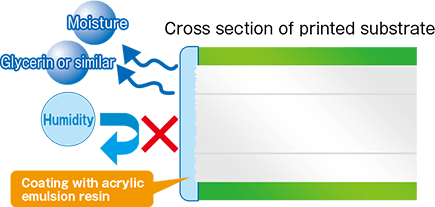

We provide Material Safety Data Sheet and various reliability test data for you to use the agent with confidence. It has excellent resistance against insulation, weather and heat and conforms to VOC regulation and RoHS compliances.

Costs

A thin application of this Substrate Edge Agent (Alpha) gives a good effect, achieving ultra-low-cost for each substrate.

Options

We provide Automatic Coating Equipment for use in both in-line and off-line.

Reliability test data

Insulation resistance test

After applying the coating agent to a comb-shaped pattern, the insulation resistance is measured during the constant temperature and humidity bias test.

| |

60℃90%RH |

Initial

time |

100h |

200h |

300h |

400h |

500h |

| Edges |

1 up |

4.5E+10 |

1.4E+10 |

2.0E+10 |

1.9E+10 |

2.0E+10 |

3.0E+10 |

| 1 down |

5.6E+10 |

1.0E+10 |

1.4E+10 |

1.6E+10 |

1.6E+10 |

3.1E+10 |

Trans

parent |

2 up |

5.3E+10 |

1.4E+10 |

1.6E+10 |

2.1E+10 |

5.6E+10 |

4.2E+10 |

| 2 down |

4.8E+10 |

1.3E+10 |

1.9E+10 |

1.7E+10 |

2.9E+10 |

5.0E+10 |

| |

25℃50%RH |

Initial

time |

After

test |

| Edges |

1 up |

5.6E+10 |

4.3E+10 |

| 1 down |

5.6E+10 |

4.8E+10 |

Trans

parent |

2 up |

3.8E+10 |

5.6E+10 |

| 2 down |

5.0E+10 |

5.0E+10 |

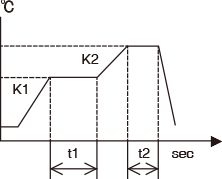

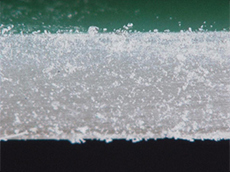

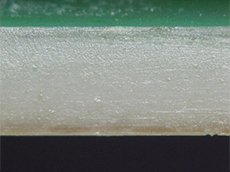

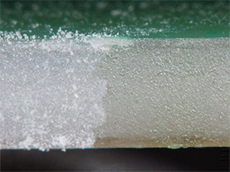

Endurance test

After leaving the sample at 25 ℃ and 50% RH for 500 hours in the constant temperature and humidity chamber, the sample is compared to the one before the test.

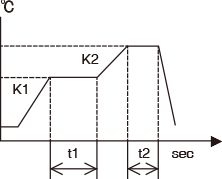

| T1(℃) |

170 |

| T2(℃) |

260 |

| t1(sec) |

60 |

| t2(sec) |

10 |

| K1(℃/sec) |

3.0 |

| K2(℃/sec) |

1.5 |