Our Electronic Equipment Division has developed "Substrate Edge Coating System" which contributes to efficient placement of workers and realization of a drastic cost reduction by achieving full automation of etching process.

An innovative system is created by our engineers, which is attracting attention in domestic and international market. We can offer you the best products to our customers always with innovative ideas and technology.

Edge Coating System

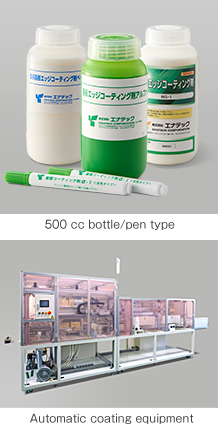

Fully automated system of etching process by Automatic Coating Equipment and Coating Agent contributes to significant cost down.

ENATECH's Edge Coating System, unique in the world, is the combination of Edge Coating Agent, which prevents dust and foreign substances from adhering to the substrate in the manufacturing process, and Automatic Coating Equipment, which can coat uniformly the four sides of the various substrates.

We have 3 types of Edge Coating Agents to suit any substrate and application: Substrate Edge Coating Agent Alpha, Edge Coating Agent for Metal Substrates, and Edge Coating Agent for Package Substrates. We have developed a wide range of product lineup from which you can choose "scale off type"* or "non-scale off type"* in accordance with the properties of your substrate manufacturing process.

*Excluding Substrate Edge Coating Agent Alpha